This determines whether or not the surface requires application of a filler to get a smoother finish.

Close grained hardwoods do not require.

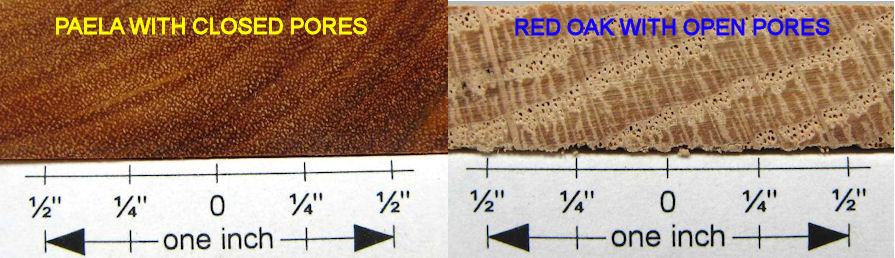

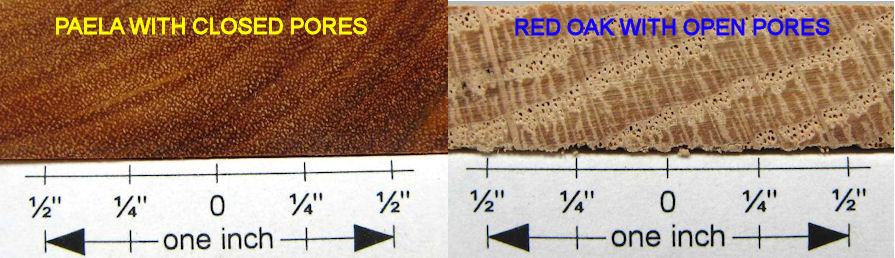

The open pores of the oak look like pin holes poked in the end.

The cellular structure of a wood influences its appearance.

Open grain hardwoods such as elm oak and ash are ring porous species.

To fill or not to fill when wood finishers refer to a hardwood as open grained or close grained they re talking about the relative size of the pores.

Does anyone know where i can find something like this.

Natural finish on close grained hardwood recipe.

Close grained wood also called fine grained wood is any wood in which the annual rings in the wood are tight or close.

End grain after shooting on a shooting board.

Birch maple cherry and others.

Close grained hardwoods like birch maple cherry and other are tricky to stain successfully.

I am looking for a detailed list that shows which woods are open grain and closed grain.

Cherry one of the most valued of hardwoods is used in fine furniture and cabinets.

Closed grain species include maple birch cherry and hickory.

Precise definitions of open and closed grained species don t exist but softwoods are generally considered open grain as is oak ash mahogany and walnut.

Cherry is close grained and does not require a filler.

Step by step instructions.

This simple no fail recipe offers clear demonstrations of all the essential steps.

This also illustrates ring porous and diffuse porous hardwoods.

These species have distinct figure and grain patterns.

Learn how to apply a lovely durable finish to close grained hardwoods like.

Close grain hardwoods such as cherry maple birch and yellow poplar are diffuse porous species.

When close grained wood is cut into lumber it has the appeal of being smooth and without the irregular characteristics of wide grained woods.

This fine textured and close grained wood does not require filling.

This refers to the texture of the wood s cell structure.

Easy fast and effective.

Learn how to get great results by following our step by step video recipe a clear finish is applied after the staining step.

Its color varies from light brown to dark reddish brown and it has a very attractive and distinctive grain often with a definite mottle.

Having medium density hardness and strength its machining and finishing properties are good as is its stability.